The 3D Printed Cabin brings many of Emerging Objects’ material, software, and hardware experiments together to demonstrate the architectural potential of additive manufacturing on a weather tight, structurally sound building. Due to a housing emergency in the Bay Area, the Oakland City Council eased restrictions on the construction of secondary housing units, or backyard cottages. This has opened the door for Emerging Objects to use the relaxed codes to experiment towards addressing housing problems at a micro scale.

The front facade has been described as a box of exquisite chocolates—comprised of a number of Planter Tile shapes and materials to create a living wall of succulents, naturally thriving in the northern California climate. Several different materials are used, including shades of portland cement, sawdust, chardonnay pomace, and combinations thereof!

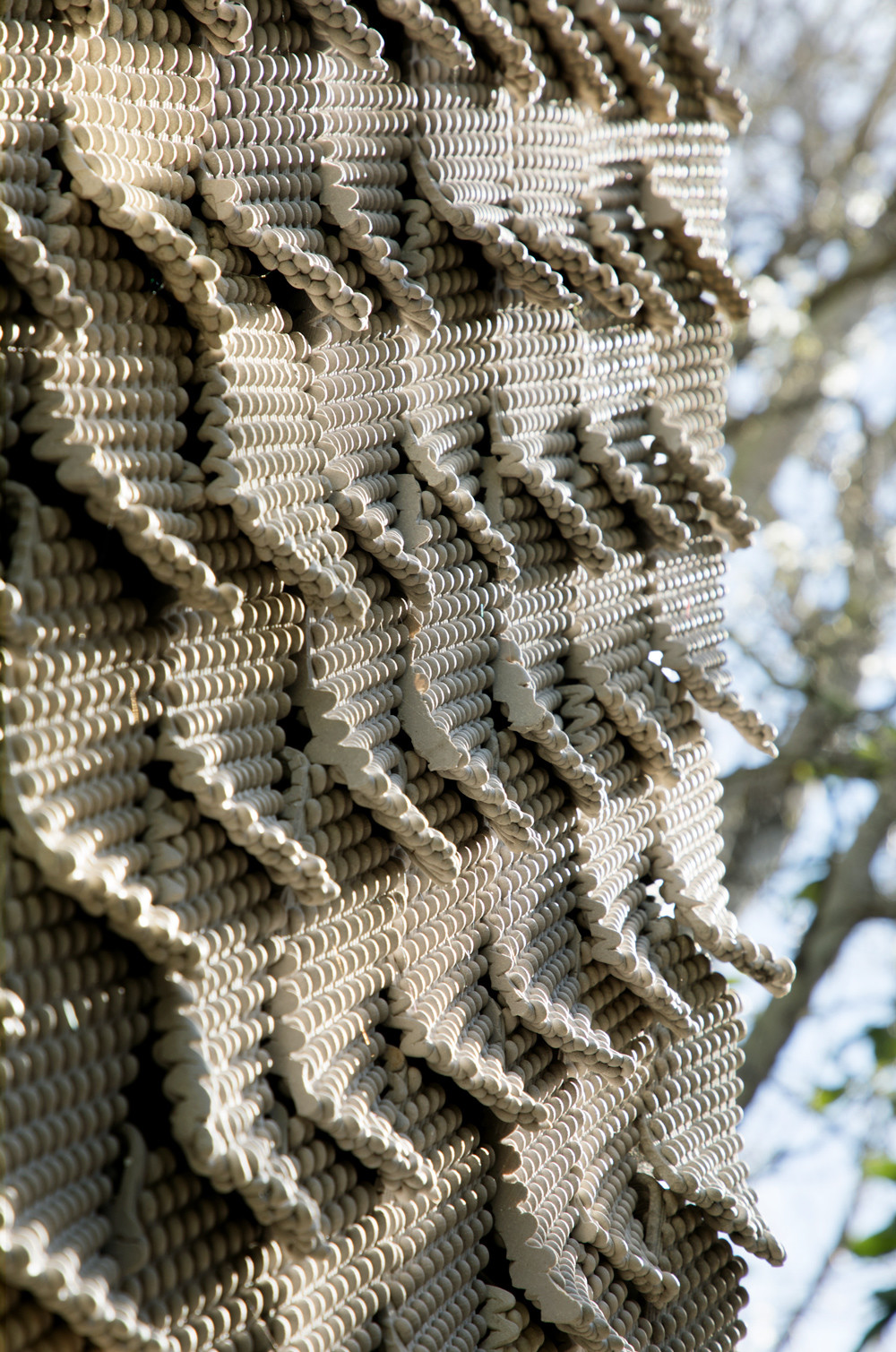

The roof and contiguous facades to the gable are clad in a 3D printed ceramic rain screen of seed stitch tiles—a 3D-printed ceramic cladding system that serves as a rain screen. Designed for easy assembly, the Seed Stitch tiles are made to be hung on a building facade or interior. The surface of each ceramic tile visually emulates a knitting technique called the seed stitch.

G-code is used to control each line of clay as it is 3D printed to create a loopy texture that looks like seeds scattered across the surface. While all ceramic tiles are printed from the same file, each tile is intentionally unique as a product of fabrication, during which the tiles wave back and forth, causing the printer to pull at the line of clay and creating longer and shorter loops toward the end of each tile, producing a distinct machine-made texture that is different every time.

The interior is clad with the Chroma Curl Wall, which not only illuminates the interior of the cabin, but also illuminates the exterior, converting the cabin into a beacon of light, but in ways that are abstract and artificial, in stark contrast to the unnatural materials that clad this humble, but spectacular, retreat. The Cabin of 3D Printed Curiosities demonstrates that 3D printing can be beautiful, meaningful, and well crafted – not crude, fast and cheap. Much like the garage makerspace movement, the backyard building space might become a platform where new ways of living are tested, new technologies can be invented and tested, and new materials can be discovered.

Project Date: 2018

Project Location: Oakland, CA

Project Team: Ronald Rael, Virginia San Fratello, Logman Arja, Hannah Cao, Sandy Curth, Barrak Darweesh, Yonghwan Kim, Daniel Komen, Cooper Rodgers, Alex Schofield, Phirak Suon, and Kent Wilson

Photography: Matthew Millaman Photography

Project Information: Special Thanks to Ehren Tool, Danny Defelici at 3DPotter, Leonard Dodd at Erectorbot, Autodesk, and The Bakar Fellows Program and Departments of Architecture and Art Practice at The University of California Berkeley. Additional thanks to Alisa Nadolishny, Natalie Yu, Anthony Gianini, and Sarah Rippee.

Press: Architects Newspaper, Designboom, Inhabitat, Archinect, ArchDaily, Curbed, 3DPrintingIndustry.com, 3DPrint.com, Dezeen.