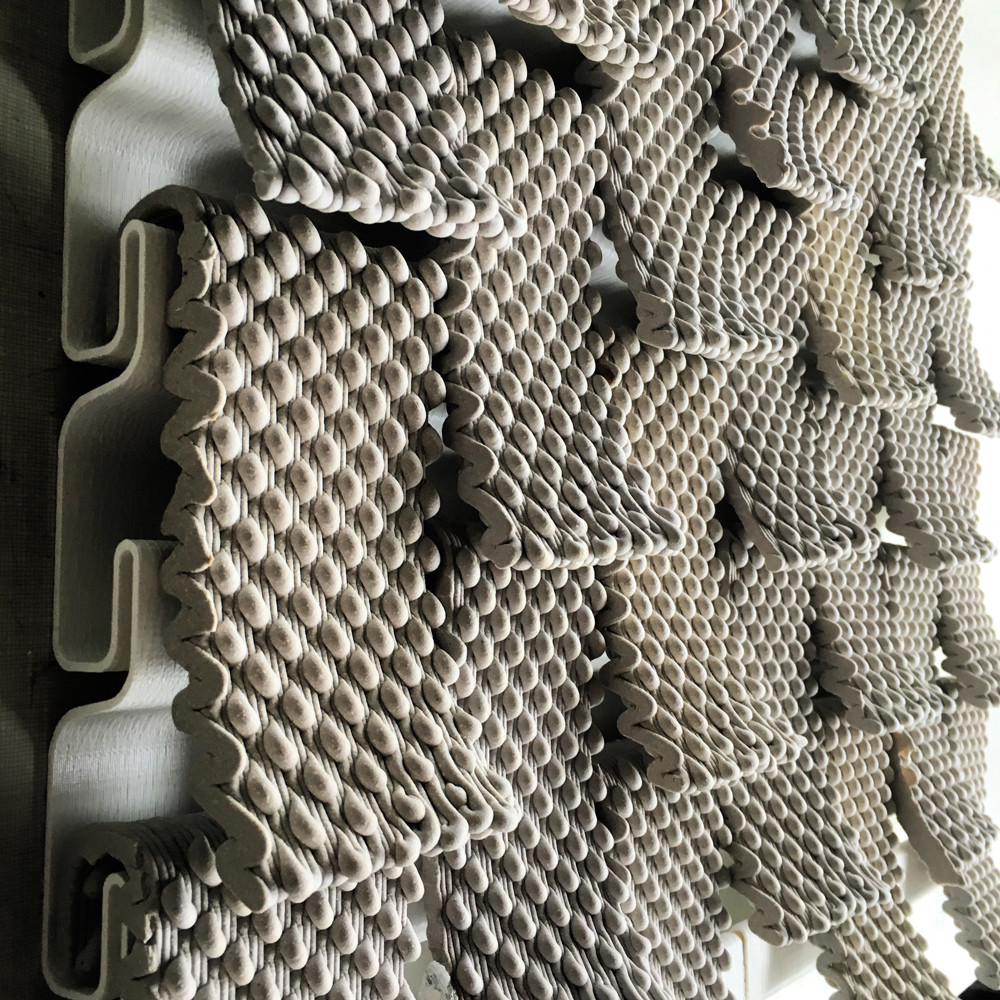

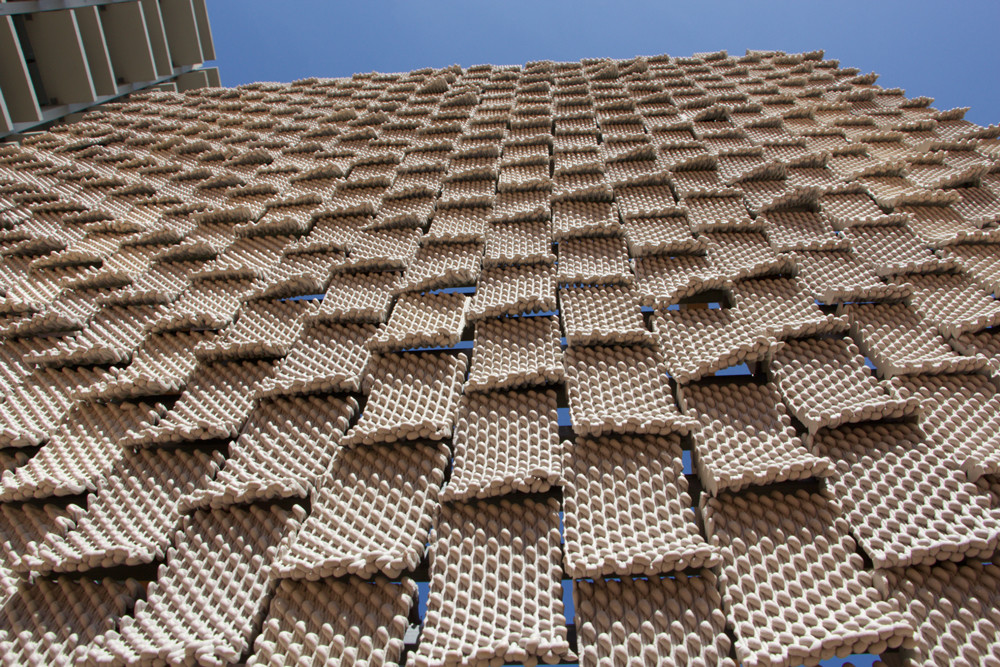

The Seed Stitch Wall is a prototype for a 3D printed ceramic wall cladding system. Whereas most applications of 3D printing demonstrate how 3D printing allows for mass difference, Seed Stitch is an exercise in mass complexity and allows the influence of the hand, gravity, temperature, and the attempts of a machine to print an unstable shape, to produce difference.

The project is inspired by our earlier experiments in manipulating gcode to produce clay surfaces that posses the texture of knitted surfaces. In knitting, the seed stitch consists of single knits and purls that alternate horizontally and vertically. Seed stitch gets its name from the texture of the knitted fabric — the little purl bumps look like scattered seeds.

At another scale, the knitted ceramic tiles, appear to have the dynamic quality of peeling, both an intentional design element and an attribute of the 3D printer pulling away at the unstable end of each ceramic tile. The machine direction, suggests another influence is shaping each tile — the wind, shrinking, or some other dynamic force, giving each type the quality of a flexible material, despite it being being a very rigid, strong, low porosity ceramic building material.

Each tile has a curve that allows it to be hung on the surface of a building. The Seed Stitch Wall employs bent galvanized metal J molding to hang the light-weight ceramic tiles. 64 square feet of surface can be hung in just minutes. Alternatively, a 3D printed backing (above) of various translucency or colors was also tested to achieve different functional and aesthetic outcomes. A translucent backing allows for backlighting of the ceramic wall for dramatic night-time effects, and can also be filled with expanded foam to create an insulated wall system.

Project Date: 2016

Project Team: Ronald Rael, Virginia San Fratello, Kent Wilson, Alex Schofield

Acknowledgments: Special thanks to Danny Defe at Deltabots, Eyal Nir at Autodesk, Ehren Tool, and the Department of Art Practice at UC Berkeley.